- Description

- Download Brochures

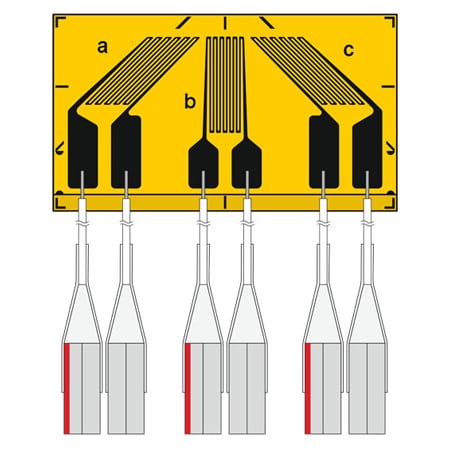

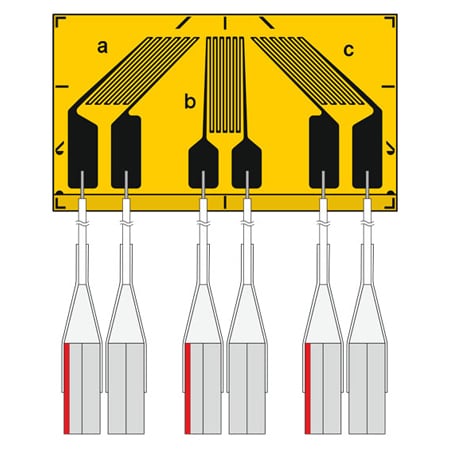

The planar rosette pattern (0 / 45°/ 90°) allows precision strain measurement by eliminating the errors often associated with a stacked pattern. These gages are available with either two 1-meter leads or three 3-meter leads per grid and are compensated for steel.

Specifications See Spec Sheet for full specifications

Strain Gage Construction Foil strain gage with embedded measuring grid

Measuring Grid

Material Constantan

Thickness µm (microinch) 3.8 or 5 (150 or 197), depending upon strain gage type

Carrier Material Polyimide

Thickness µm (microinch) 45 ± 10 (1.772 ± 394)

Connections PTFE wire, Ø - 0.051 mm², approximately 50 mm long, connected to AWG 28 ribbon cables (PVC insulated) through solder sleeves in 2- or 3-wire configurations

Nominal Resistance Ω 120 or 350 depending upon gage

Resistance Tolerance % ±0.35, with 0.6 mm and 1.5 mm grid length % ±1

Gage Factor approximately 2 (stated on package)

Gage Factor Tolerance % ±1, with 0.6 mm and 1.5 mm grid length % ±1.5, temperature coefficient of gage factor 1/K [1/°F] (115 ± 10) x 10-6 [(64 ± 5.5) x 10-6, nominal value of gage factor temperature coefficient Specified on each package

Applicable Bonding Materials

Cold Cure Adhesives SG496, SG401

Heat Cure Adhesives TT300

Specifications See Spec Sheet for full specifications

Strain Gage Construction Foil strain gage with embedded measuring grid

Measuring Grid

Material Constantan

Thickness µm (microinch) 3.8 or 5 (150 or 197), depending upon strain gage type

Carrier Material Polyimide

Thickness µm (microinch) 45 ± 10 (1.772 ± 394)

Connections PTFE wire, Ø - 0.051 mm², approximately 50 mm long, connected to AWG 28 ribbon cables (PVC insulated) through solder sleeves in 2- or 3-wire configurations

Nominal Resistance Ω 120 or 350 depending upon gage

Resistance Tolerance % ±0.35, with 0.6 mm and 1.5 mm grid length % ±1

Gage Factor approximately 2 (stated on package)

Gage Factor Tolerance % ±1, with 0.6 mm and 1.5 mm grid length % ±1.5, temperature coefficient of gage factor 1/K [1/°F] (115 ± 10) x 10-6 [(64 ± 5.5) x 10-6, nominal value of gage factor temperature coefficient Specified on each package

Applicable Bonding Materials

Cold Cure Adhesives SG496, SG401

Heat Cure Adhesives TT300

- Choosing a selection results in a full page refresh.

- Opens in a new window.