Torque Multiplier vs Torque Wrench Calibration Differences

When it comes to precision torque tools, the two most commonly discussed pieces of equipment are torque multipliers and torque wrenches. While both are essential in industrial and mechanical settings, many professionals and technicians often wonder about the key differences between the two, especially in terms of torque wrench calibration. Understanding these differences can help ensure accurate results, increased safety, and longer equipment lifespan.

In this comprehensive blog post, we’ll dive into the main contrasts between torque multipliers and torque wrenches, explore their calibration needs, and explain why torque wrench calibration services are critical for maintaining optimal tool performance.

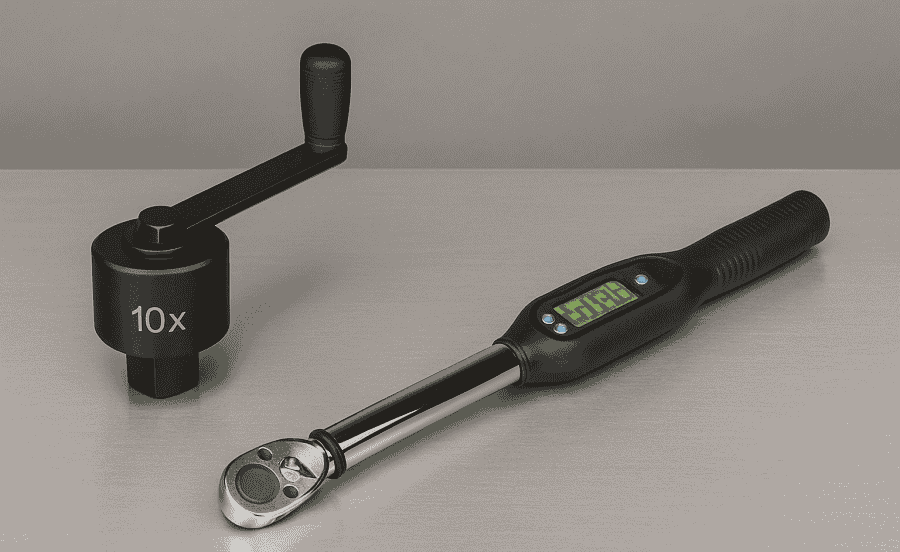

What Is a Torque Wrench?

A torque wrench is a precision tool used to apply a specific amount of torque to fasteners like bolts and nuts. It ensures that components are neither too loose nor too tight, which is crucial in applications ranging from automotive repairs to aerospace engineering.

Types of Torque Wrenches

Click Torque Wrenches: Clicks when a preset torque is reached.

Beam Torque Wrenches: Uses a scale and pointer; simple yet reliable.

Digital Torque Wrenches: Offers real-time torque readings and data storage.

Torque wrenches require periodic torque wrench calibration to ensure their accuracy remains within acceptable limits.

What Is a Torque Multiplier?

A torque multiplier is a device used to increase the torque output applied to a fastener without increasing the amount of effort applied by the operator. It’s typically used when high torque levels are needed, and using a traditional torque wrench would be inefficient or physically demanding.

Common Applications:

➥Heavy equipment maintenance

➥Oil and gas pipelines

➥Construction and shipbuilding

Unlike torque wrenches, torque multipliers usually work through a system of gears and require less frequent calibration. However, they still need to be checked for accuracy in high-precision settings.

Key Differences Between Torque Multipliers and Torque Wrenches

| Feature | Torque Wrench | Torque Multiplier |

|---|---|---|

| Function | Measures and applies torque | Multiplies torque output |

| Calibration Frequency | Regularly required | Less frequent, but necessary |

| Accuracy Level | High | Depends on gear ratio and setup |

| Common Use | Precision fastening | High-torque applications |

| Portability | Lightweight and compact | Heavier and larger |

Understanding these differences helps you choose the right tool for your specific application and ensures that you're scheduling appropriate torque wrench calibration services when needed.

Importance of Torque Wrench Calibration

Torque wrench calibration is the process of adjusting the torque wrench to ensure it delivers the correct torque value as specified by its manufacturer. With frequent use, even high-end torque wrenches can drift from their calibrated settings, resulting in inaccurate torque application.

Why Calibration Matters:

➥Prevents equipment damage

➥Ensures compliance with industry standards

➥Improves safety

➥Enhances measurement accuracy

In professional settings, especially those dealing with critical loads or safety-sensitive components, uncalibrated torque tools can lead to disastrous consequences.

Torque Wrench Calibration vs Torque Multiplier Calibration

Though both tools can benefit from calibration, the process and importance differ.

Torque Wrench Calibration:

Usually performed every 6-12 months

Requires a torque wrench calibration tool such as a torque tester or digital transducer

Carried out using precise weights or hydraulic setups

Torque Multiplier Calibration:

➥Depends on frequency of use

➥More mechanical in nature, focusing on gear integrity

➥Often validated using a calibrated torque wrench

Since torque multipliers rely on gear mechanisms, their accuracy depends on correct ratios. Although not as frequently calibrated as torque wrenches, overlooking their calibration can still cause costly errors.

How Torque Wrench Calibration Tools Work

A torque wrench calibration tool is used to verify and adjust the accuracy of a torque wrench. It typically consists of a test fixture, a known resistance, and a readout device to measure the applied torque.

Common Calibration Tools:

➥Hydraulic calibration rigs

➥Electronic torque analyzers

➥Beam-style testers

These tools simulate real-world conditions and allow technicians to detect any deviation in torque application.

When to Calibrate Your Torque Tools

Calibrating your tools isn't just a recommendation it’s often a requirement in industrial environments. Here are some tell-tale signs and schedules to keep in mind:

When to Calibrate:

After 5,000 cycles of use

Following a heavy drop or mishandling

Before critical applications

As part of routine maintenance every 6-12 months

Keeping a calibration log is a good practice to help track tool performance and identify patterns in calibration drift.

Choosing the Right Tool for Your Application

When deciding between a torque wrench and a torque multiplier, consider:

Required Torque Level: Use a torque multiplier for high-torque settings.

Precision Needs: Torque wrenches offer better precision.

Working Conditions: Space constraints may favor compact torque wrenches.

Frequency of Use: Heavier-duty torque multipliers are built for intensive, repetitive tasks.

Often, both tools are used together torque multipliers to increase torque and torque wrenches to fine-tune.

HK Calibrations and Their Role in Precision Calibration

HK Calibrations has built a reputation for offering Professional torque wrench calibration services across Australia. Their experience with a wide range of calibration equipment, including torque wrench calibration tools, makes them a trusted name in the industry.

Their facilities are equipped to handle:

➥Standard torque wrench calibration

➥High-capacity torque multipliers

➥On-site and lab-based services

They support industries such as:

➥Automotive

➥Aerospace

➥Construction

➥Energy and utilities

HK Calibrations also offers advanced digital calibration devices, ensuring that clients meet ISO standards and internal QA requirements. Their tools are used by professionals who can't afford to compromise on torque accuracy.

Conclusion

Torque wrenches and torque multipliers may serve similar goals ensuring proper fastener tension but they do so in fundamentally different ways. Understanding the nuances in their design, use, and calibration needs is key to making informed decisions.

While torque wrench calibration is more frequently required, overlooking calibration on torque multipliers can also be costly. Using appropriate torque wrench calibration tools and scheduling timely torque wrench calibration services are vital steps in any serious maintenance or manufacturing operation.

Whether you're handling delicate electronics or assembling heavy machinery, calibrated torque tools ensure that every bolt and nut is tightened to perfection. And when precision matters, trust industry-tested names like HK Calibrations to keep your tools in check.