How to Choose Electrical Calibration Equipment for Business

Whether you're running an industrial plant, an electronics repair facility, or a calibration lab, having the right electrical equipment calibration tools is essential for safety, performance, and compliance. But with so many brands and electrical equipment suppliers on the market, choosing the right setup can be overwhelming.

In this blog, we’ll break down the core considerations you should keep in mind when selecting calibration equipment for your business and how to ensure your instruments align with Electrical Appliance Testing standards.

What is Electrical Equipment Calibration?

Electrical calibration is the process of verifying and adjusting the precision of instruments that measure electrical quantities such as voltage, current, resistance, inductance, capacitance, and frequency. It ensures your devices operate within specified tolerances and deliver accurate readings.

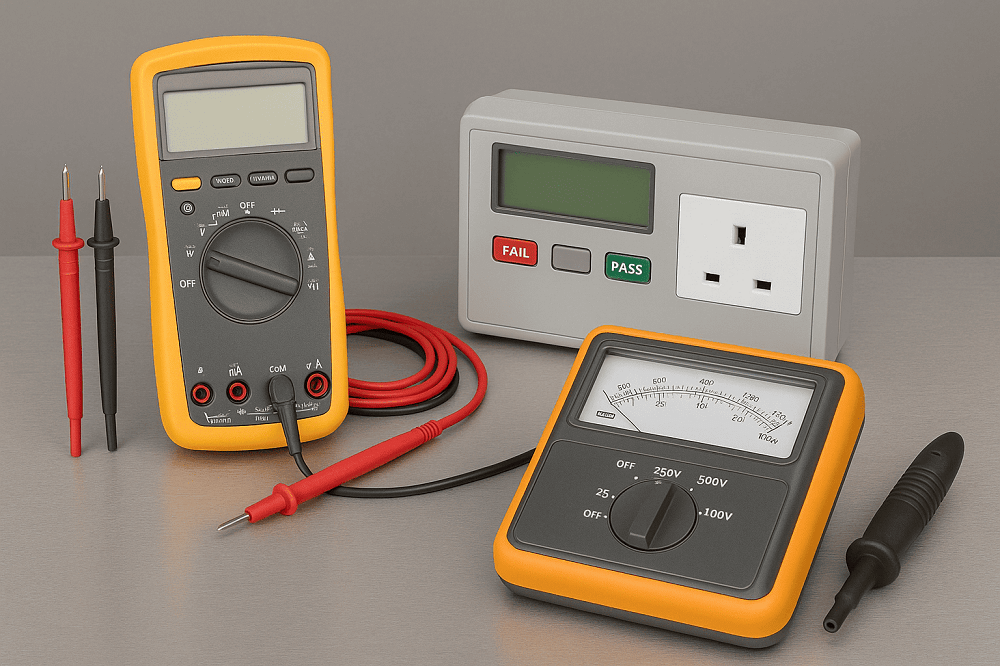

Businesses that rely on equipment like:

➥Multimeters

➥Oscilloscopes

➥Insulation testers

➥Clamp meters

➥Power supplies

Why Electrical Calibration Matters for Your Business

✅ Compliance with Industry Standards

Regulatory bodies like ISO/IEC 17025 require businesses to maintain a traceable calibration system. If you're in manufacturing, automotive, aerospace, or energy, skipping calibration can risk non-compliance and product recalls.

✅ Enhanced Accuracy

Faulty readings can result in poor performance or even dangerous situations. Calibrated equipment provides peace of mind and better decision-making.

✅ Prolonged Equipment Life

Regular electrical equipment calibration prevents wear and tear, catching issues before they become expensive failures.

✅ Trust & Quality Assurance

Clients and auditors value businesses that prioritize accuracy and standards. Being aligned with proper Electrical Appliance Testing procedures shows your commitment to quality.

Types of Electrical Calibration Equipment

Before reaching out to electrical equipment suppliers, it’s essential to understand the various types of calibration instruments your business might need. The right tools ensure precise electrical equipment calibration and compliance with safety standards like Electrical Appliance Testing.

1. Multimeter Calibrators

Used for verifying the accuracy of handheld digital and analog multimeters. These are essential for facilities that rely on voltage, current, and resistance measurements.

2. Oscilloscope Calibrators

These calibrators test the bandwidth, amplitude, and timing accuracy of oscilloscopes—crucial for labs and electronic diagnostics.

3. Insulation Tester Calibrators

Ensure reliable insulation resistance measurements in power distribution systems, helping detect faults and avoid equipment breakdowns.

4. Loop Calibrators

Measure and source process loop signals, typically 4–20 mA. These are ideal for industrial process control systems and instrumentation maintenance.

5. Portable Appliance Testers (PAT Testers)

PAT testers are vital for Electrical Appliance Testing, ensuring that portable electrical devices are safe and compliant with workplace safety regulations.

How to Choose the Right Electrical Calibration Equipment

1. Define Your Business Needs

What equipment are you calibrating?

Do you require Electrical Appliance Testing compliance?

How often will you perform calibrations?

Are you setting up an in-house lab or need portable tools?

2. Review Calibration Ranges & Accuracy

Always select equipment that exceeds the accuracy requirements of the devices you're testing. For example, to calibrate a multimeter with ±0.5% accuracy, your calibrator should have at least 4–10x higher precision.

3. Look for Traceability & Certificates

Always choose calibration tools that come with traceable certificates to national/international standards like NIST or ISO/IEC 17025.

4. Choose Reputable Electrical Equipment Suppliers

Don’t cut corners here. A quality supplier provides not just tools but also:

✔ Technical support

✔ Documentation

✔ Software integration

✔ On-site training if needed

Seek suppliers with a good track record in industries like power, electronics, and instrumentation.

5. Evaluate User Interface & Portability

User-friendly software, intuitive interfaces, and wireless capabilities (like Bluetooth or USB data transfer) can improve technician productivity. Compact, portable units are ideal for field technicians.

HK Calibrations – A Trusted Name in Electrical Calibration

Businesses across Australia rely on HK Calibrations for top-tier tools and calibration services. Their range of electrical equipment calibration tools supports various industries, from medical and automotive to heavy electrical manufacturing.

HK’s offerings include:

◆ High-accuracy multimeter and loop calibrators

◆ PAT testers for Electrical Appliance Testing

◆ Precision insulation resistance calibration tools

◆ Equipment with traceable certification and support

Their tools are compatible with both in-lab and field-based testing environments, ensuring flexibility for growing businesses.

In-House Calibration vs Third-Party Services

If you’re still unsure whether to invest in calibration tools or outsource the service, here’s a quick comparison:

| Feature | In-House Calibration | Third-Party Services |

|---|---|---|

| Control | High | Moderate |

| Cost | High upfront, low long-term | Pay-per-service |

| Turnaround Time | Instant | Varies |

| Certification | Depends on setup | Often ISO-certified |

| Flexibility | High | Medium |

Businesses with frequent testing needs and in-house technicians often benefit more from owning their own electrical equipment calibration setup.

Tips for Electrical Appliance Testing (PAT Testing)

PAT Testing is a legal and safety requirement in many industries. Here are some tips when selecting equipment:

✔ Choose testers with both Class I and Class II support

✔ Opt for tools that can test extension leads and surge protectors

✔ Ensure your tester has clear pass / fail indicators

✔ Consider devices with data logging and Bluetooth reporting

Some PAT testers come with barcode scanning and result storage, which is useful for tracking assets over time.

How Often Should You Calibrate Electrical Equipment?

The general rule is:

High-use devices: Every 6 months

Moderate use: Annually

Critical systems: As per manufacturer or regulatory guidance

Routine calibration ensures your instruments stay within tolerance and helps catch potential faults early.

Conclusion

Investing in the right electrical equipment calibration tools is a strategic move that safeguards your business, enhances performance, and ensures compliance. Whether you’re buying from a local electrical equipment supplier or expanding your Electrical Appliance Testing capabilities, the right choices today can streamline operations and boost long-term efficiency.

Looking for reliable calibration tools? HK Calibrations offers some of the best in the industry highly accurate, user-friendly, and built for professionals.