7 Things to Consider Before Buying Metrology Instruments

Choosing the right metrology instruments is a critical decision for any manufacturer, laboratory, or quality control department. These tools are designed to provide precise measurements, improve production efficiency, and maintain product quality, but selecting the wrong instrument can lead to wasted resources, inaccurate results, and costly downtime. To help you make an informed decision, here are seven essential factors to consider before purchasing metrology instruments.

1. Accuracy and Precision Requirements

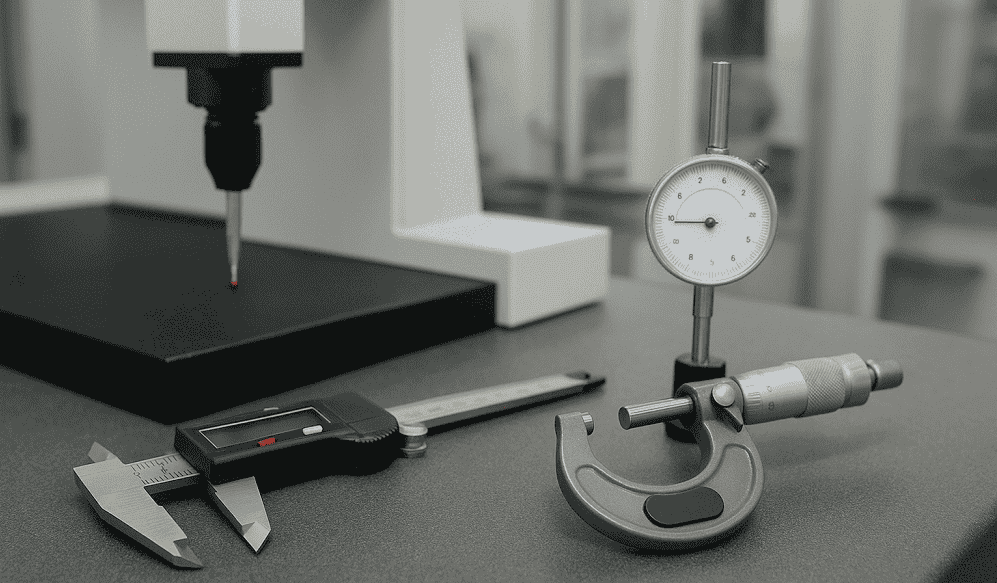

Accuracy is the foundation of metrology. Before purchasing, clearly define the level of accuracy and precision your operations require. Metrology instruments vary widely in their capabilities. For instance:

Digital calipers and micrometers: Suitable for micrometer-level precision, ideal for smaller parts and components.

Coordinate Measuring Machines (CMMs): Achieve sub-micrometer accuracy, essential for highly complex and critical components.

Laser scanners and optical comparators: Offer non-contact measurement for delicate or irregular surfaces.

Understanding your specific measurement needs is vital. Overestimating your requirements can lead to unnecessary expenses, while underestimating can compromise product quality. By defining precise tolerances and accuracy requirements upfront, you can select instruments that match your operational goals.

2. Measurement Range and Capacity

Not all instruments are suitable for every application. It is important to consider the size and range of the components you will be measuring:

Small components: Micrometers, dial indicators, and compact calipers are efficient and cost-effective.

Medium to large components: Height gauges, depth gauges, and surface plates may be required.

Complex geometries or large-scale assemblies: CMMs, laser trackers, and 3D scanning systems provide the necessary flexibility.

Choosing an instrument with the appropriate measurement range prevents limitations in production and ensures that you won’t need additional tools for future projects. A well-planned investment today saves both time and money in the long run.

3. Type of Measurement Needed

Metrology instruments are specialized for different types of measurements. Before purchasing, determine whether your needs are focused on:

Linear dimensions: Length, width, height, depth.

Angular measurements: Critical for mechanical components requiring precise alignment.

Surface or roughness analysis: Important in finishing processes where smoothness affects performance.

Force, pressure, or temperature measurements: Essential in testing environments and industrial applications.

Selecting the right type of instrument ensures accurate results and avoids unnecessary expenditures on equipment that may not be fully compatible with your measurement requirements.

4. Ease of Use and Training Requirements

Advanced metrology instruments can be complex, requiring skilled operators to deliver accurate results. Consider:

User interface: Instruments with intuitive screens, automated features, and digital readouts reduce errors and improve efficiency.

Training needs: Some systems require extensive training, which may impact timelines and labor costs.

Support from manufacturers: Warranty, troubleshooting assistance, and training programs add long-term value.

A tool that is user-friendly and requires minimal training can significantly reduce operational downtime and human error while maximizing productivity.

5. Durability and Maintenance

Metrology instruments are long-term investments, and their durability is crucial. Evaluate:

Material quality: Instruments made from robust materials like hardened steel or high-grade alloys resist wear and tear.

Environmental resistance: Instruments should withstand temperature fluctuations, humidity, and vibrations if used in industrial settings.

Maintenance requirements: Regular calibration and servicing ensure sustained accuracy and prolong lifespan.

Selecting instruments with high durability and low maintenance needs reduces ongoing costs and prevents disruptions caused by equipment failure.

6. Integration with Existing Systems

Modern manufacturing increasingly relies on integrated systems for data collection, quality analysis, and reporting. When purchasing metrology instruments, consider:

Connectivity: Can the instrument integrate with your quality management software or production system?

Data logging capabilities: Automated data collection minimizes manual errors and provides traceable records for audits.

Real-time monitoring: Some advanced systems allow for immediate feedback during production, enabling quick corrections and reducing defects.

Integration capabilities not only improve efficiency but also provide actionable insights for continuous improvement in production processes.

7. Cost and Long-Term Value

Cost is an important factor, but it should be evaluated in the context of long-term value:

Initial investment vs. ROI: High-quality instruments may seem expensive upfront but can save money by reducing waste, defects, and labor costs.

Operational savings: Instruments that increase efficiency, minimize downtime, and prevent errors contribute to significant cost reductions over time.

Scalability: Consider whether the instrument can adapt to future measurement needs or expansions.

A carefully planned investment in metrology instruments ensures that you are not only meeting current requirements but also positioning your business for sustainable growth.

Additional Considerations

Calibration frequency: Ensure instruments can be calibrated efficiently and accurately. Frequent calibration requirements can add to operational costs.

Software updates and compatibility: Instruments that receive regular software upgrades maintain accuracy and can incorporate new functionalities.

Supplier reputation: Choosing a reliable supplier with strong support services ensures long-term reliability and peace of mind.

Conclusion

Purchasing metrology instruments is more than just acquiring tools; it is a strategic investment in accuracy, efficiency, and cost savings. By carefully considering accuracy, range, measurement type, ease of use, durability, system integration, and long-term value, businesses can select instruments that support operational excellence while minimizing risks and unnecessary costs.

A well-informed decision ensures that your metrology tools deliver reliable, precise measurements, improve production efficiency, reduce waste, and enhance product quality. Investing wisely today in high-quality, modern metrology instruments not only strengthens your manufacturing process but also positions your business for long-term competitiveness and profitability.